Laser cleaning is a versatile surface treatment technology that is gaining traction in the cleaning of industrial applications. Its ability to remove contaminants with precision and minimal damage makes it ideal for tasks like paint removal in car restoration or rust removal from delicate machinery. However, the power of the laser beam extends far beyond what we initially think it does. Researchers are constantly exploring new and surprising ways to utilise this technology for cleaning applications across various industries.

This blog looks at five unexpected applications of laser cleaning systems that showcase its versatility and potential to revolutionise cleaning methods in various sectors.

What is Laser Cleaning?

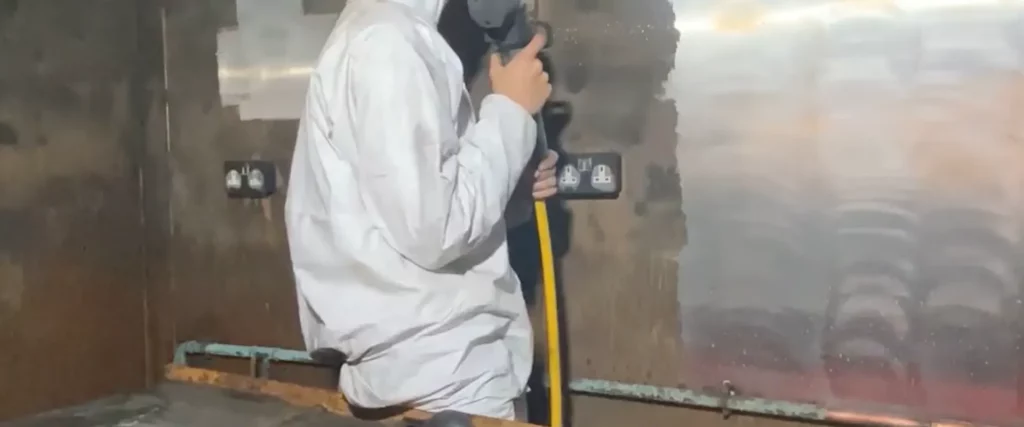

Firstly, let’s understand what laser cleaning actually is, and what it does. Laser cleaning utilises a highly focused beam of light to remove unwanted materials from a surface. Here’s a breakdown of the process:

- Laser Beam:

The cleaning system uses a high-power laser, typically a pulsed fibre laser. These lasers emit short bursts of intense light energy. - Material Interaction:

When the laser beam strikes the surface, a portion of the energy is absorbed by the contaminant. This absorbed energy rapidly heats the contaminant, causing it to vaporise or experience a change in state (like turning from solid to gas). - Precise Laser Ablation:

The key to laser cleaning lies in the concept of “ablation.” Ablation refers to the removal of material from a surface through the application of energy. By carefully controlling the laser’s wavelength and power, we can target only the contaminant, minimising impact on the underlying surface (substrate). - Contaminant Removal:

The vaporised or altered contaminant is then ejected from the surface, leaving behind a clean and undamaged base material.

Art Restoration Using Laser Cleaning Technology

Art restoration is a delicate process. Chemical cleaning methods or the use of abrasive tools can damage the artwork’s surface or alter its original colours. Laser cleaning offers a gentler alternative that using harsh solvents. Here’s where laser cleaning steps in – offering a precise and controlled surface cleaning method.

By carefully adjusting the laser’s wavelength and power, restorers can target specific contaminants like dirt, grime, and even varnish layers with minimal impact on the underlying artwork. This allows for the removal of unwanted layers while preserving the delicate details and original pigments.

Laser cleaning solutions have proven particularly effective in cleaning murals and frescoes. High-powered lasers can be used for large-scale cleaning, while lower-powered lasers with fine control can tackle intricate details. This technology can also be used to remove unwanted graffiti without damaging the underlying brick or stonework.

Archaeological Discoveries Using Laser Cleaning Technology

Archaeologists often face the challenge of cleaning and preserving artefacts unearthed from their slumber beneath impurities such as layers of dirt, grime, and even mineral deposits. Traditional methods like manual brushing or water jets can damage delicate objects.

A laser cleaning process offers a solution, allowing archaeologists to meticulously clean artefacts while preserving their intricate details and any remaining traces of paint, pigment, or other materials that might hold historical significance.

For example, laser cleaning has been used to reveal inscriptions on ancient pottery shards that were previously obscured by dirt and corrosion. It has also been used to clean delicate fossils, removing layers of sediment to reveal the intricate details of the creature it once belonged to.

The high precision nature of laser cleaning ensures that only the targeted material is removed, leaving behind a clean surface for further analysis and preservation.

Uses Of Laser Cleaning Technology In The Food Processing Sector

Food safety is paramount in the food processing industry. Maintaining a clean and hygienic environment is crucial to prevent contamination and ensure the quality of food products. Traditional cleaning methods using harsh chemicals can leave residues and raise concerns about food safety.

Laser cleaning offers a viable alternative. By targeting specific contaminants like mould, bacteria, adhesive bonding on new kitchen installations, and even charring on metal surfaces, lasers can effectively clean without leaving any harmful residues. This ensures a cleaner and safer environment for food production on typical stainless steel surfaces while eliminating the need for harsh chemicals.

Furthermore, laser cleaning can be used to remove biofilms – a complex layer of bacteria that can be difficult to remove using traditional methods. This can significantly reduce the risk of foodborne illnesses.

The ability to clean hard-to-reach areas on equipment is another advantage of laser cleaning. This ensures a more thorough cleaning process, further enhancing food safety standards.

Medical Applications of Laser Cleaning

Maintaining sterility is crucial in the medical field, especially for surgical instruments. Traditional cleaning methods involving harsh chemicals or autoclaves can damage delicate instruments over time.

Use of laser systems offer a gentler and more effective alternative. By precisely targeting contaminants and organic matter on the surface areas of surgical instruments, lasers can achieve thorough sterilisation without compromising the integrity of the instruments. This ensures patient safety and reduces the risk of infections during surgery.

Laser cleaning can also be used as a surface texturing tool to clean delicate medical implants prior to surgery. This ensures a sterile surface that promotes better integration with the patient’s body and reduces the risk of rejection.

Laser Technology in the Automotive Industry

Laser cleaning has the potential to be a game-changer in the world of car restoration and maintenance. Here’s a closer look at how it can be applied to automobiles:

- Paint Removal and Restoration: Laser cleaners can be used for precise paint removal during car restoration projects. By carefully controlling the laser’s power and focus, it can remove unwanted layers of paint without damaging the underlying metal or previous paint layers you want to preserve. This allows for a more controlled approach compared to traditional methods like sanding or chemical strippers, which can be aggressive and risk damaging the car’s body.

- Laser Rust Removal: Rust is an iron oxide and many cars see this appear over time. Laser cleaning is effective in removing rust from car parts. The pulsed laser beam targets the rust particles, heating them rapidly and causing them to detach from the metal surface. This is a particularly beneficial option for delicate areas or components where traditional methods like wire brushes or sandblasting might be too harsh and cause gouging or warping.

- Undercarriage Cleaning: Laser cleaning machines can be used to tackle tough grime and undercoating buildup on a car’s undercarriage. The focused laser beam can reach into nooks and crannies, removing stubborn dirt and debris that traditional pressure washing might miss.

- Engine Component Cleaning: Laser cleaning can be used for cleaning delicate engine components like valves, pistons, and intake manifolds. The precise nature of the cleaning process ensures removal of contaminants without damaging the intricate parts, making laser technology the best and most cost-effective choice for cleaning metal.

Laser Cleaning Technology FAQs

What surface preparation steps should be taken before laser cleaning?

Remove any loose contaminants, pre-clean any heavily soiled areas with care and mask sensitive areas that may be affected by the laser beam.

Can laser cleaning technology be used as a pre-treatment step?

Laser cleaning can be used as a pretreatment step before further processing or coating application.

Does laser surface cleaning produce any toxic emissions?

Laser cleaning technology itself doesn’t necessarily produce toxic emissions, but it depends on the underlying materials that are being removed.

Can lasers be used on plastics?

Low-power lasers are effective for cleaning delicate surfaces like those encountered in plastic restoration or coating removal from metals without damaging the underlying material.

Choose Lasertec for Your Laser Cleaning Needs

We pride ourselves on our agility whilst maintaining strict adherence to health and safety regulations.

We’ve spent years working with a vast array of clients in all industries and gained a deep understanding of how laser cleaning can be deployed to save time and money for each application. Through this process, we’ve evolved and continue to evolve our systems and techniques to be as effective as possible.

Whether you need to remove paint, rust, or other contaminants, Lasertec can provide the right laser cleaning solution for you. It is an effective and efficient method for cleaning various materials, and it is safe and non-destructive.

Our goal is to provide our clients with the best laser cleaning services in the UK, serving all sectors with industrial cleaning solutions. We are committed to providing the highest quality services, at competitive prices. Our team of experienced technicians will ensure you get the best results, every time. Our innovative processes ensure the best results possible.