Laser Cleaning vs Grit Blasting: Cost, Downtime & Environmental Comparison (UK Industrial Guide)

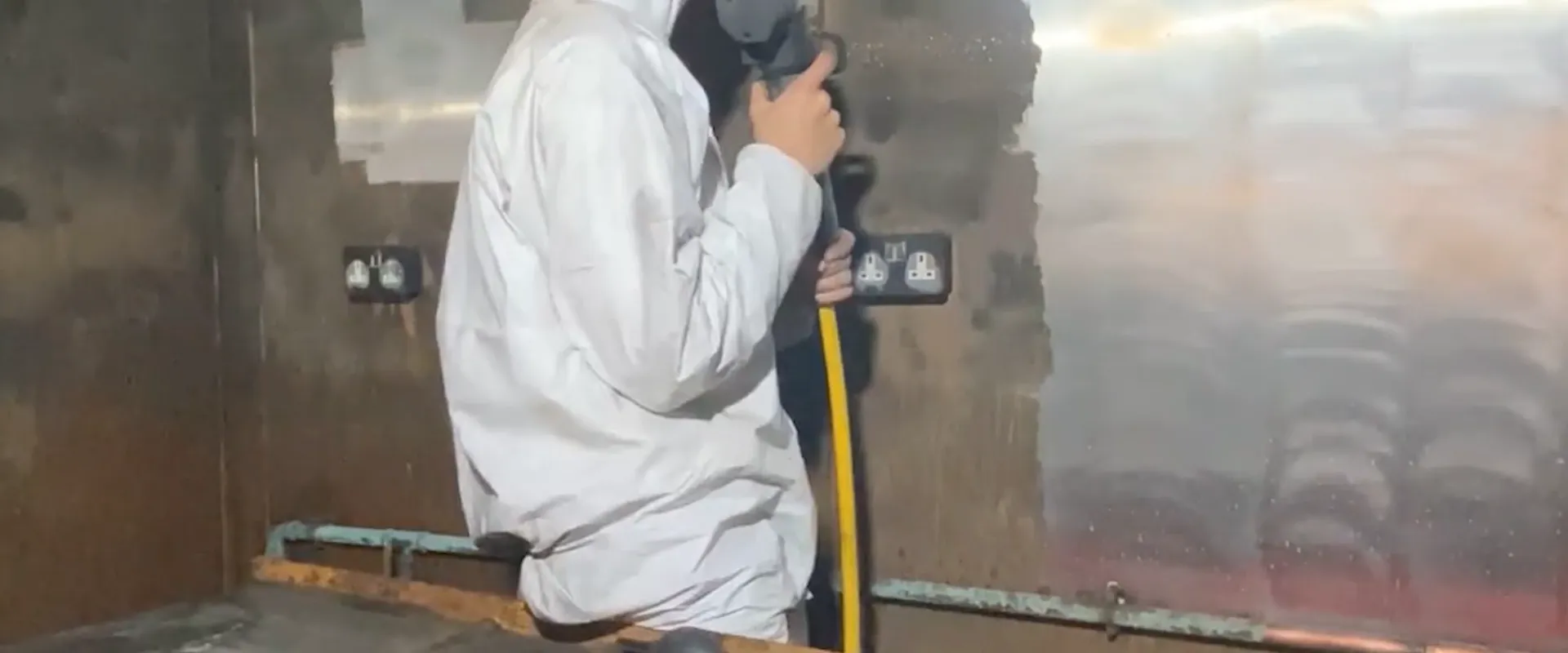

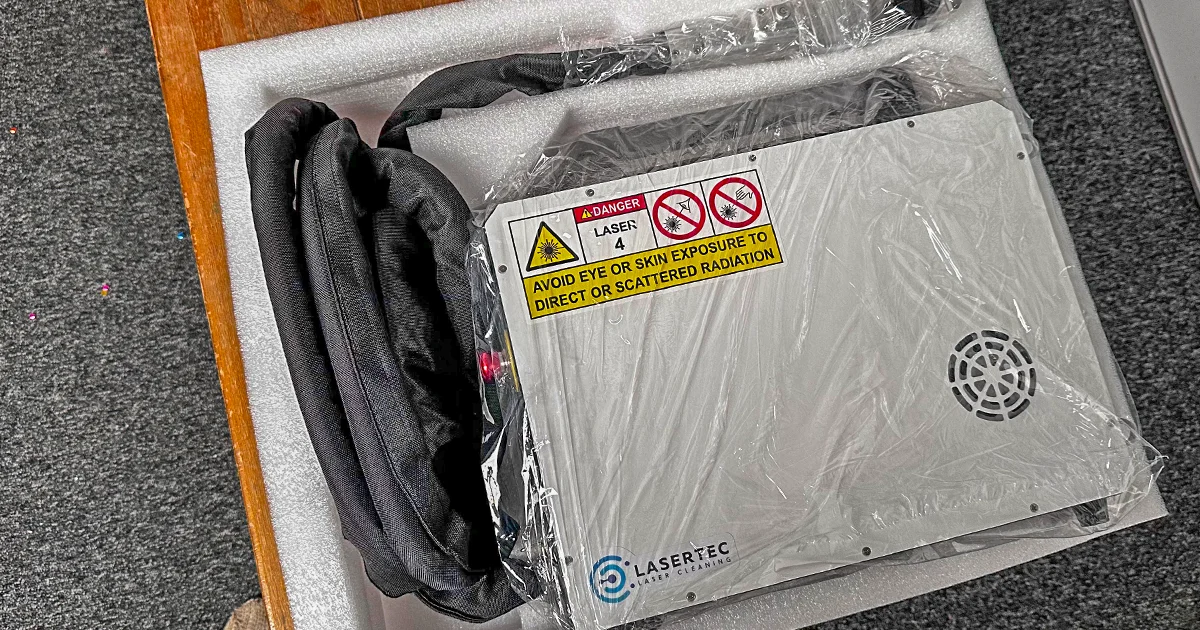

Grit blasting has long been the default method for industrial surface preparation. However, fibre laser cleaning is increasingly being specified across UK infrastructure, rail, aerospace