Laser cleaning is an advanced method for removing contaminants such as rust, paint, and coatings from various surfaces. It offers significant advantages over traditional techniques, including greater precision, reduced material damage, and a lower environmental footprint. The process is fast, highly efficient, and produces no secondary waste or by-products, making it ideal for sensitive or controlled environments.

However, the ablation process produces fine particulate matter and gaseous emissions, including metal oxides, volatile organic compounds (VOCs), and toxic by-products from coatings and plastics. These airborne contaminants pose significant health risks without effective fume extraction and safety measures.

This article explores the health risks associated with laser cleaning fumes, the importance of fume extraction systems, and key strategies for ensuring a safe working environment.

Understanding Laser Cleaning and Fume Production

Laser cleaning uses high-intensity laser beams to ablate contaminants from surfaces. The energy is absorbed when the laser interacts with materials such as rust, paint, or oils, causing the unwanted layer to vaporise or dislodge without damaging the underlying surface.

While this process eliminates the need for chemical solvents, it generates airborne contaminants that must be managed effectively. These can include:

- Metal oxides from rust removal and coatings.

- Volatile organic compounds (VOCs) from paint and adhesives.

- Toxic by-products from plastics, such as dioxins, cyanides, and heavy metals.

Proper fume extraction and containment are essential to ensure a safe and compliant working environment.

Health Risks Associated with Laser Cleaning Fumes

Exposure to laser-generated fumes depends on the ablated materials, exposure duration, and ventilation quality. While laser cleaning eliminates chemical-based solvents, it does not eliminate the risks posed by airborne contaminants.

Respiratory Risks & Particulate Inhalation

Laser ablation produces microscopic particles that can penetrate deep into the lungs. Inadequate fume extraction increases the risk of chronic respiratory conditions, including:

- Bronchitis & Occupational Asthma – Resulting from prolonged irritation caused by fine particulates.

- Chronic Obstructive Pulmonary Disease (COPD) – Leading to long-term lung function impairment.

Toxic Fume Exposure & Systemic Effects

Some materials emit hazardous gases that affect the nervous system, liver, and kidneys. Examples include:

- Lead Oxides & Chromium Fumes – Found in industrial coatings and linked to neurological damage and metal fume fever.

- Dioxins & Cyanides – Released from plastics and synthetic coatings, both highly toxic and potentially carcinogenic.

Regulatory Concern: Workplace Exposure Limits (WELs)

In the UK, Workplace Exposure Limits (WELs) set maximum permissible levels of hazardous airborne contaminants. Exposure levels can exceed these limits without effective fume extraction, increasing long-term occupational risks.

Employers must ensure compliance with safety regulations by implementing effective fume extraction and air monitoring systems.

The Importance of Fume Extraction Systems

Fume extraction is critical to maintaining air quality, equipment performance, and regulatory compliance.

An effective fume extraction system serves three primary functions:

- Protecting Worker Health – Removing airborne contaminants before they reach the operator’s breathing zone prevents respiratory issues and toxic fume exposure.

- Maintaining Equipment Integrity – Preventing particulate buildup on laser optics and machinery reduces downtime and maintenance costs.

- Ensuring Cleaning Precision – Eliminating airborne obstructions, maintaining clear laser pathways for optimal cleaning results.

Key Features of an Effective Fume Extraction System

For maximum protection and efficiency, an effective fume extraction system should include:

1. Multi-Stage Filtration

High-performance extraction systems use multiple filtration layers to capture a wide range of contaminants:

- HEPA filters – Capture 99.97% of ultrafine particles as small as 0.3 microns.

- Activated carbon filters – Neutralise hazardous gases and VOCs.

- Pre-filters – Capture larger particulates, extending the lifespan of HEPA filters.

2. Adequate Airflow & Suction Power

Extraction units must be powerful enough to remove fumes at the source. Inadequate suction results in poor containment, spreading contaminants into the workspace.

3. Localised vs. Room-Wide Ventilation

- Localised extraction (e.g., flexible arms, hoods) captures fumes at the source, preventing dispersion.

- Room-wide ventilation systems may be necessary in larger industrial settings.

4. Routine Maintenance & Filter Replacement

Filters lose efficiency over time. Regular inspections and scheduled replacements ensure continued fume extraction performance.

Integrating Safety Measures for Laser Cleaning Operations

Ensuring compliance with UK health and safety regulations requires a multi-layered approach, combining engineering controls, material identification, PPE, and air monitoring.

Engineering Controls & Fume Extraction

To effectively capture and contain fumes, LaserTec employs:

- Local Exhaust Ventilation (LEV) systems capture fumes at the source.

- Fully enclosed workstations where required.

- HEPA and activated carbon filtration technology for optimal air quality control.

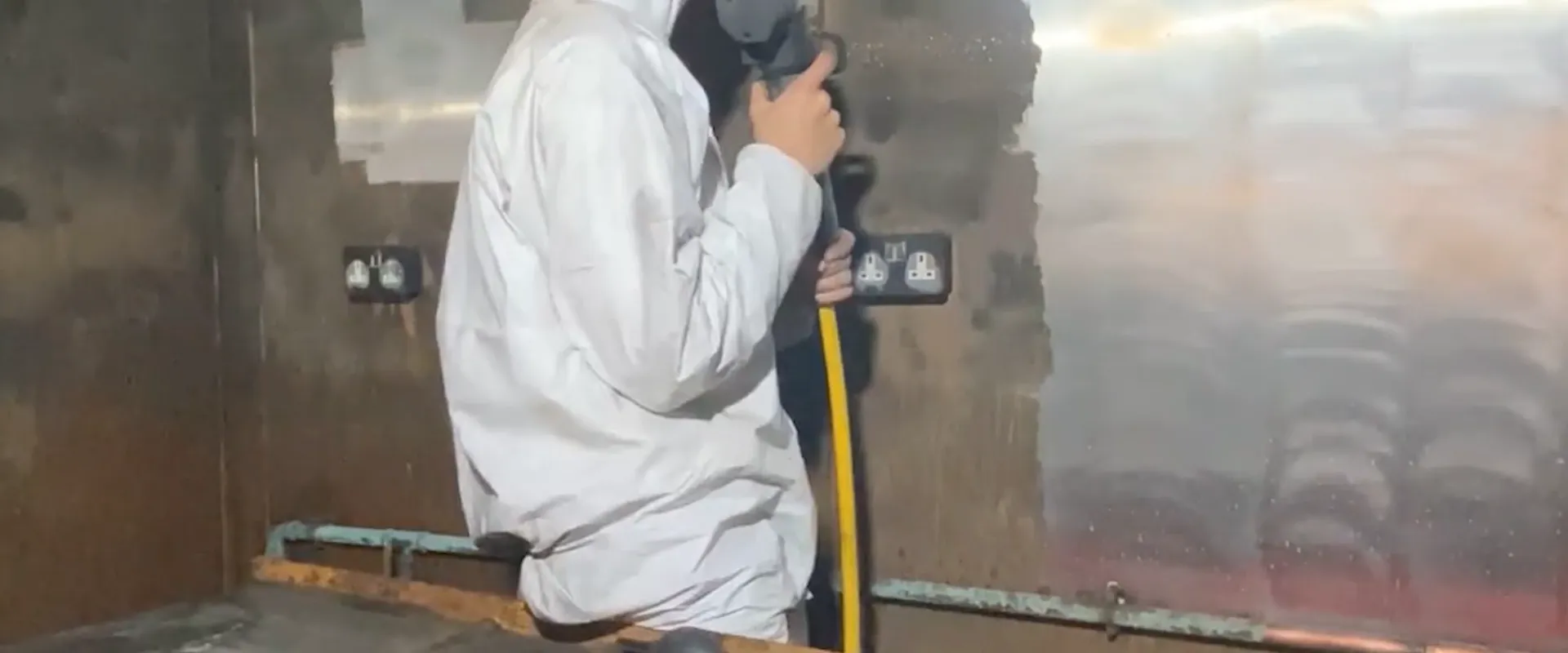

- Full hooded RPE for enhanced respiratory protection in high-risk environments.

Personal Protective Equipment (PPE)

Laser cleaning operators at LaserTec use high-quality PPE, including:

- Fully hooded air fed respirators.

- Laser-rated goggles, visors, and face shields specific to our laser’s wavelengths for eye and face protection.

- Heat-resistant gloves and coveralls to prevent contact with hot or toxic particulates.

Air Monitoring & Routine Maintenance

Where necessary, LaserTec conducts routine air quality checks to detect metal fumes (e.g., Cr(VI), Pb) and chemical vapours (e.g., formaldehyde, HCl). Our LEV systems and respirators undergo regular filter replacement to maintain safe operating conditions.

Administrative Controls & Operator Safety Protocols

To minimise risk, LaserTec restricts laser operation to trained professionals, enforces lockout/tagout (LOTO) procedures, and implements strict laser safety protocols.

Ensuring Compliance with Health and Safety Regulations

Businesses using laser cleaning technology in the UK are required to follow health and safety regulations to protect workers from potential hazards associated with laser-generated fumes. This includes managing exposure to airborne contaminants, ensuring proper ventilation, and implementing effective safety controls.

LaserTec prioritises safety and compliance by integrating advanced fume extraction systems, high-performance filtration technology, and rigorous air monitoring procedures. Our approach aligns with industry best practices and recognised safety guidelines, ensuring a controlled and compliant working environment.

Conclusion

Fume extraction is not optional, but a critical requirement for safe and effective laser cleaning. By investing in high-quality filtration, sufficient airflow, and routine maintenance, businesses can maximise cleaning efficiency while prioritising safety and regulatory compliance.

LaserTec sets the industry standard for safe, compliant, and efficient laser cleaning operations by continuously investing in advanced fume extraction technology and strict safety protocols.

To find out more about our laser cleaning services or speak to our team about safety and compliance measures, get in touch with LaserTec today.