Laser Cleaning Safety is at the forefront of adopting advanced technologies in the cleaning industry, especially when dealing with high-value assets like aircraft and military vehicles. While laser cleaning is a safer alternative to conventional cleaning methods, understanding and adhering to safety protocols is essential to maximize its benefits.

Understanding Laser Cleaning Safety

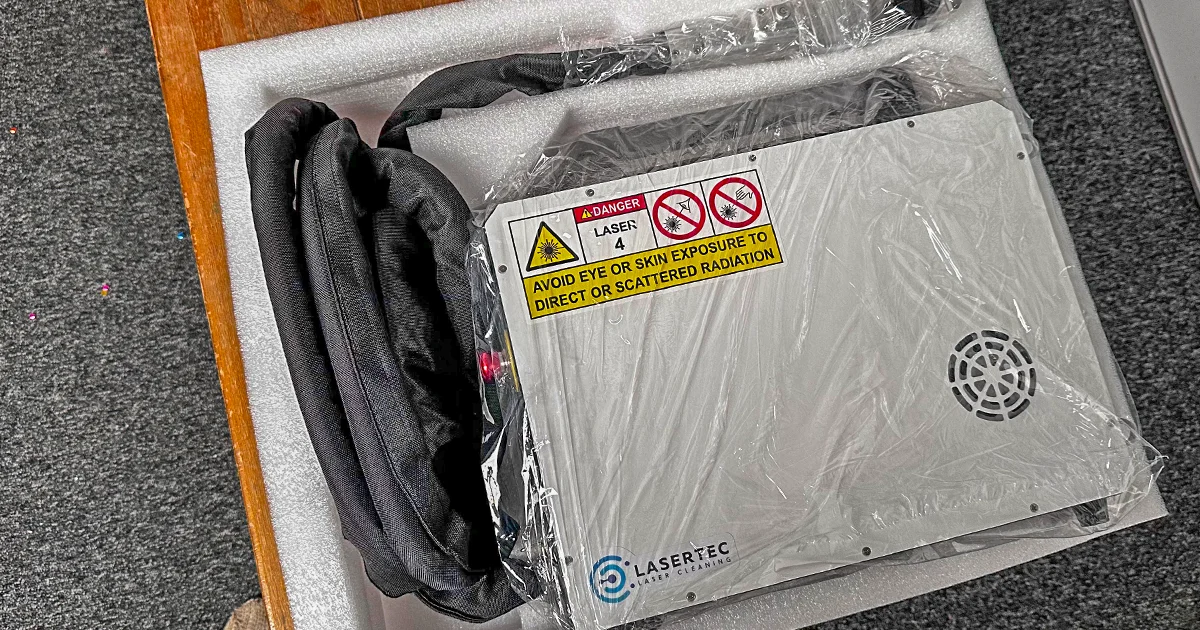

Laser Cleaning Safety begins with understanding what laser cleaning is. This method is an advanced, non-conductive, and non-damaging approach, known for being environmentally friendly for both metal and non-metal applications. It operates by directing focused laser pulses to remove surface contaminants such as rust, oil, and grease. This technology is particularly effective in applications like welding treatments, coating preparation, mold tool cleaning, nuclear decontamination, and surface preparation for Non-Destructive Inspection (NDI).

Key Aspects of Laser Cleaning Safety

- Laser Safety Enclosures: A critical component of Laser Cleaning Safety is the use of enclosures in stationary laser cleaning setups. These enclosures protect operators and bystanders from potential laser reflections and ensure the laser only operates under safe conditions, with interlocking mechanisms for additional safety.

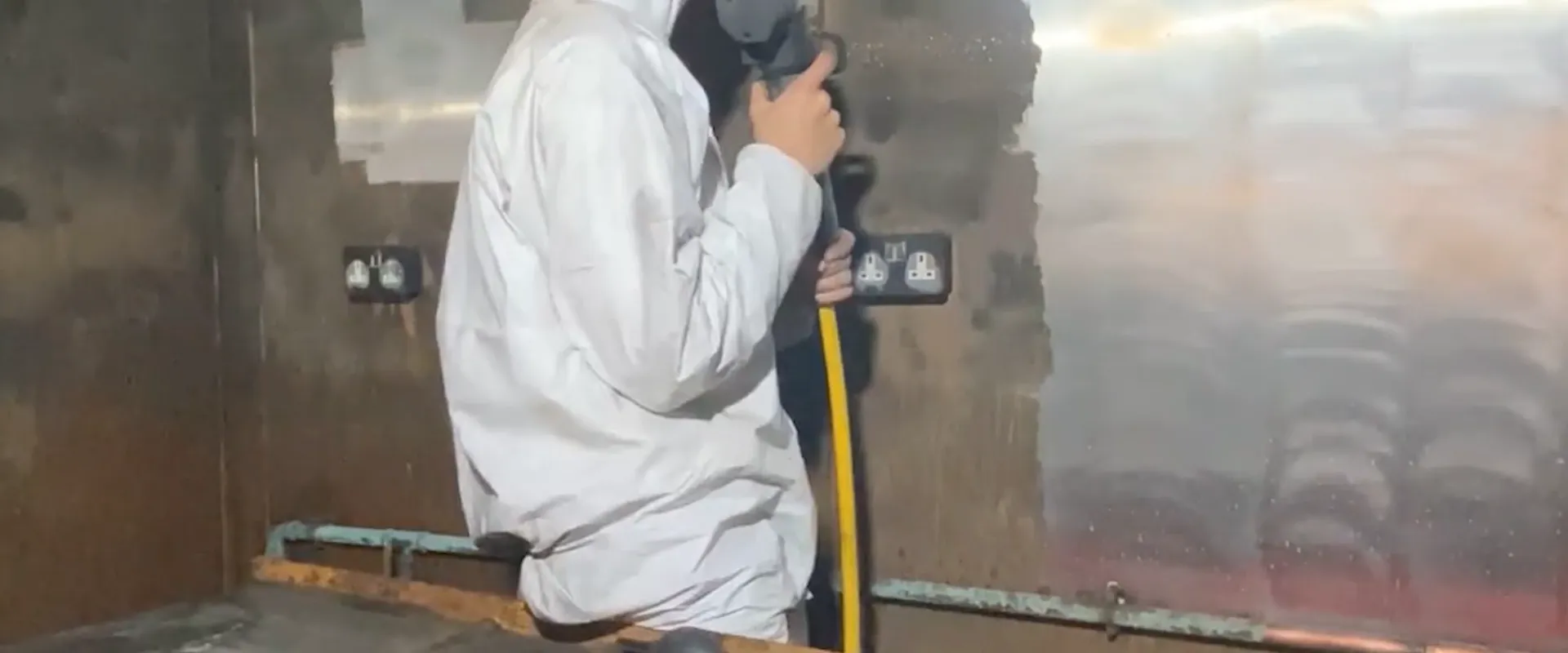

- Personal Protective Equipment (PPE): For portable laser cleaning, creating a designated hazard zone is crucial for Laser Cleaning Safety. Operators and anyone entering this zone must wear appropriate laser safety glasses. Controlling the area with signage and understanding the safety procedures is essential, especially since direct and indirect laser emissions can be harmful to eyes and skin.

- Additional Safety Considerations:

- Managing Airborne Contaminants: A significant aspect of Laser Cleaning Safety involves managing airborne contaminants, particularly when dealing with hazardous paints.

- Electrical Safety: Compliance with electrical safety standards is a crucial element of Laser Cleaning Safety, especially when operating high-voltage laser systems.

- Flammability Risks: Recognising flammability risks, especially with non-metallic materials, is essential for Laser Cleaning Safety. Ensuring that combustible materials are removed from the cleaning area is a key precaution.

Adapt Laser’s Role in Promoting Laser Cleaning Safety

Adapt Laser is at the forefront of providing laser cleaning solutions, with a keen focus on Laser Cleaning Safety. Our range of products and comprehensive training programs encompass safety procedures, equipment operations, maintenance, and troubleshooting, ensuring the safe and efficient use of laser cleaning technology.

Conclusion

Laser Cleaning Safety is a critical component in the evolving landscape of cleaning technologies. With proper safety measures and training, laser cleaning not only offers superior cleaning efficiency but also ensures a safe working environment, making it an indispensable tool in various industrial applications.